Sensitivity & Tolerance

An optimised optical design that meets the desired performance criteria might miserably fail when facing manufacturing tolerances in production or environmental conditions in the real world. While low yields of requirement compliant parts are acceptable when setting up a prototype they can become a show stopper for large volume and even small-batch production due to a substantial increase in finished product costs.

On the other hand even finished products that meet the optical requirements under controlled laboratory conditions are useless when they are oversensitive to vibration or temperature variations typically encountered in the field.

We can help you with sensitivity- and tolerance-analysis that takes deviations introduced by thermal-, structural-, integration- and machining-effects into account.

*doi: 10.1117/12.3014257

*doi: 10.1117/12.3014257

Our services comprise:

- manufacturing tolerance survey of the assembly components

- identification of critical tolerance parameters for the complete assembly

- identification of critical environment induced tolerances

- optical simulations covering the range of critical parameter tolerances

- simulation analysis to find a tolerance optimised design

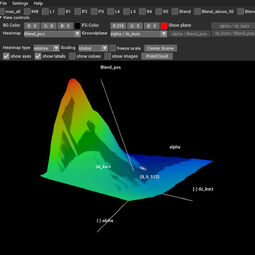

More often than not the search for the optimal performance of an optical system results in a tolerance sensitive design because the optimisation process found a steep maximum in parameter space. A small deviation in one of the critical design parameters does therefore induce a large performance degradation with regard to the defined requirements. The goal is to create a design that provides a flat maximum for the optimal parameter combination as well as to find this maximum.

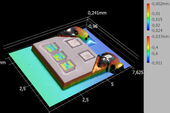

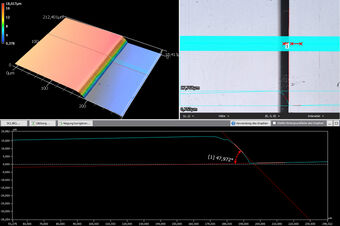

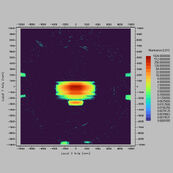

After a first step, in which the tolerance parameters are identified and quantified we perform optical simulations that cover the range of tolerances to discover the most critical parameters. This can already eliminate bad design variants or highlight possibilities for design changes that make the system more resilient. In the next step, we perform detailed simulations for the set of critical parameters to better understand how they are related.

*doi: 10.1117/12.3014257

*doi: 10.1117/12.3014257

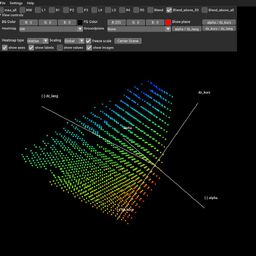

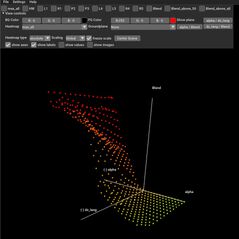

To make an educated decision about necessary design modifications we have developed an application that visualises the simulation results in the multidimensional parameter space.

The application allows to dynamically change the visualised dimensions, extract slices at selectable positions and apply performance constraints to exclude non conformant regions of the parameter space.

*doi: 10.1117/12.3014257

*doi: 10.1117/12.3014257

It helps to gain insight which design elements of the system need to be modified to match the performance requirements and identify flat regions of performance values in parameter space.

*doi: 10.1117/12.3014257 Development of cost-efficient micro-optics for headlight systems, SPIE Optical Systems Design 2024

doi: 10.1117/12.2296071 Tackling sun intrusion: a challenge of close collaboration of thermal, mechanical, structural and optical engineers, International Conference on Space Optics - ICSO 2016

doi: 10.1515/aot-2018-0039 Stray light and ghosts in catadioptric spectrometers incorporating grating scatter measurements into simulations and ghost sensitivity into system design, J. Adv. Opt. Techn. 2018